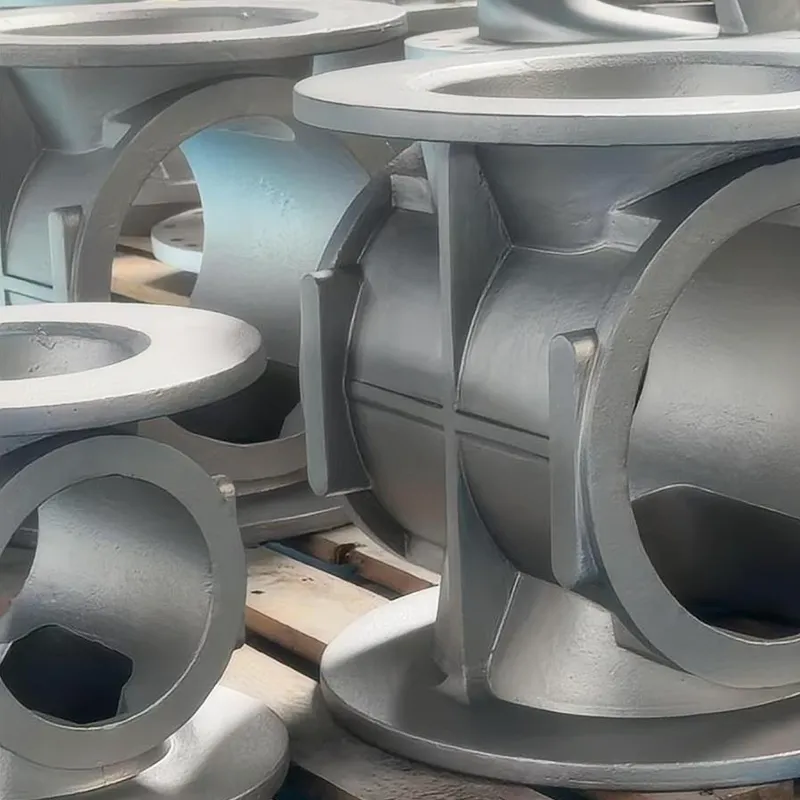

Products

Investment casting

Keywords:

Investment casting

- Details

-

Investment casting, also known as lost-wax casting, is an ancient yet advanced metal forming process centered around a precision wax pattern. This process involves: creating a meltable wax pattern using CNC machining or 3D printing → coating the wax pattern with multiple layers of silica sol and zircon sand to form a ceramic shell → vaporizing the wax to create a mold cavity → pouring molten alloy (such as stainless steel, titanium alloy, or superalloy) → breaking the shell to remove the finished part.

■ Main Features

Excellent mold accuracy: The ceramic shell achieves ultra-high precision, with mold cavity replication errors less than 0.05 mm, capable of forming highly complex hollow structures, curved surfaces, and fine textures (minimum aperture of 0.3 mm).

■ Core Advantages

Ultra-precise tolerances: Achieves ±0.1mm dimensional tolerances and a mirror-like surface finish (Ra 1.6-6.3μm), reducing machining allowance by up to 90%.

Wide material compatibility: Supports a variety of materials, from carbon steel and aluminum alloys to nickel-based superalloys, with casting temperatures exceeding 1600℃.

Flexible production volume: Economical for both single-piece and mass production of thousands of pieces, making it ideal for customized high-end components.

Seamless design integrity: The integral ceramic shell eliminates parting lines, prevents misalignment, and enhances structural integrity.

Investment casting possesses the core capabilities of "limitless precision and strong material versatility," making it an indispensable solution for high-end complex metal parts. It is widely used in aerospace, medical devices, jewelry, energy, and defense industries. Especially against the backdrop of new material innovation and miniaturization trends, investment casting will continue to lead the precision manufacturing industry into the future.■ Applicable Materials

304 stainless steel, 316L stainless steel, 2202 stainless steel, 2507 stainless steel, 904L stainless steel, 2205 stainless steel, 1Cr18Ni9Ti, CD4mcu

More Products

Casting process products

-

Investment casting

This process involves: fabricating a meltable wax model using a CNC machine or 3D printing → coating the wax model with multiple layers of silicon sol and zircon sand to form a ceramic shell → steam dewaxing to form a cavity → casting molten alloys (such as stainless steel, titanium alloy or superalloys) → breaking the shell to remove the finished part.

-

Lost foam casting

Lost foam casting is an advanced casting technology that uses a foam pattern as the main mold. Its core principle is to replace the traditional mold with a foam pattern; during pouring, the high-temperature molten metal vaporizes the foam and fills the cavity.

-

Sand casting

Sand casting is one of the most traditional metal forming processes, using quartz sand or special sand combined with clay or resin binders to make molds. Metal parts can be produced by gravity or pressure casting.

-

Resin sand casting

Resin sand casting: Uses resin as a binder, mixed with sand to form a mold. Resin sand casting has low mold costs and is suitable for large and complex castings, generally used for machine tools, lathes, large machinery bases, etc.

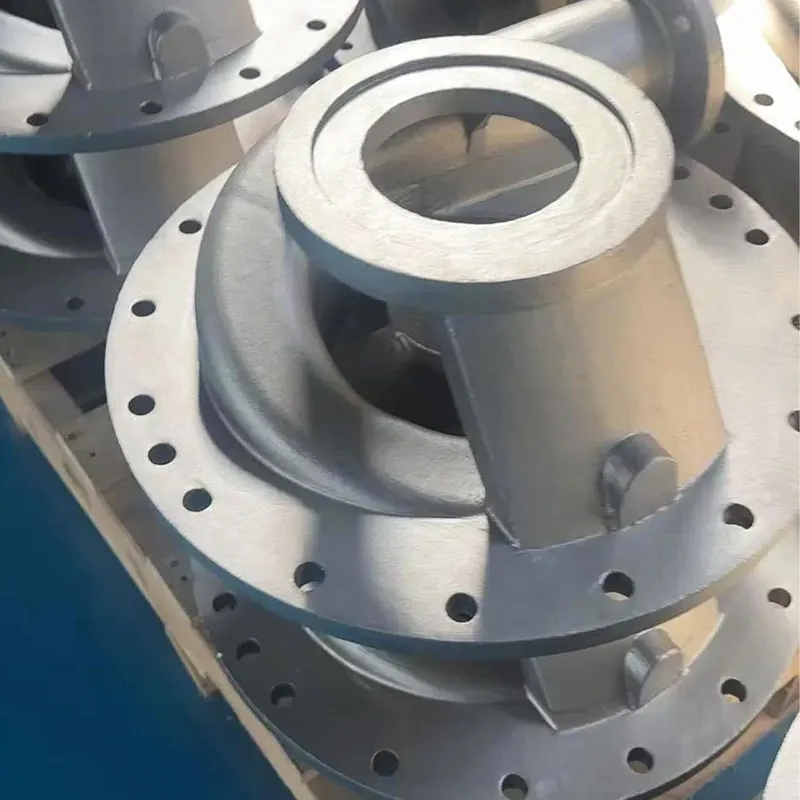

Filter Pump Body

Multistage Pump Body

-

Multistage pump bodies

Expertise in manufacturing products with complex structures: equipped with advanced casting simulation software to assist in process and product design.

-

Roots blower pump body

The company specializes in the research and development, production, and sales of a wide range of high-quality pump bodies and Roots blower components.

Double-Suction Pump Body

-

350S44 Double-suction pump bodies

Linear dimensions: GB/T 1800.1-2009 standard grade 5-7; Geometric dimensions: GB/T 1800.1-2009 standard grade 6-8.

-

Double-suction pump bodies

These products are widely used in industries such as chemical engineering, petroleum, pharmaceuticals, electric power, environmental protection, and metallurgy, providing reliable fluid transfer solutions for numerous enterprises worldwide.

Mixed-Flow Pump Body

Vacuum Pump Body

Chemical Pump Body

Roots Blower Components

-

Roots blower components

Expertise in manufacturing products with complex structures: equipped with advanced casting simulation software to assist in process and product design.

-

Multi-stage pump guide vanes

Its main products include double-suction pump bodies, multistage pump bodies, mixed-flow pump bodies, vacuum pump bodies, Roots blower accessories, chemical pump bodies, as well as impellers.

Impeller

-

Impeller (Paper machinery industry)

Stainless steel, carbon steel, low alloy steel, medium alloy steel, copper alloy, aluminum alloy, nickel-based alloy, cobalt-based alloy, etc.

-

Impeller

Stainless steel, carbon steel, low alloy steel, medium alloy steel, copper alloy, aluminum alloy, nickel-based alloy, cobalt-based alloy, etc.