Products

Lost foam casting

Keywords:

Lost foam casting

- Details

-

Lost Foam Casting: An advanced casting process centered around foam patterns

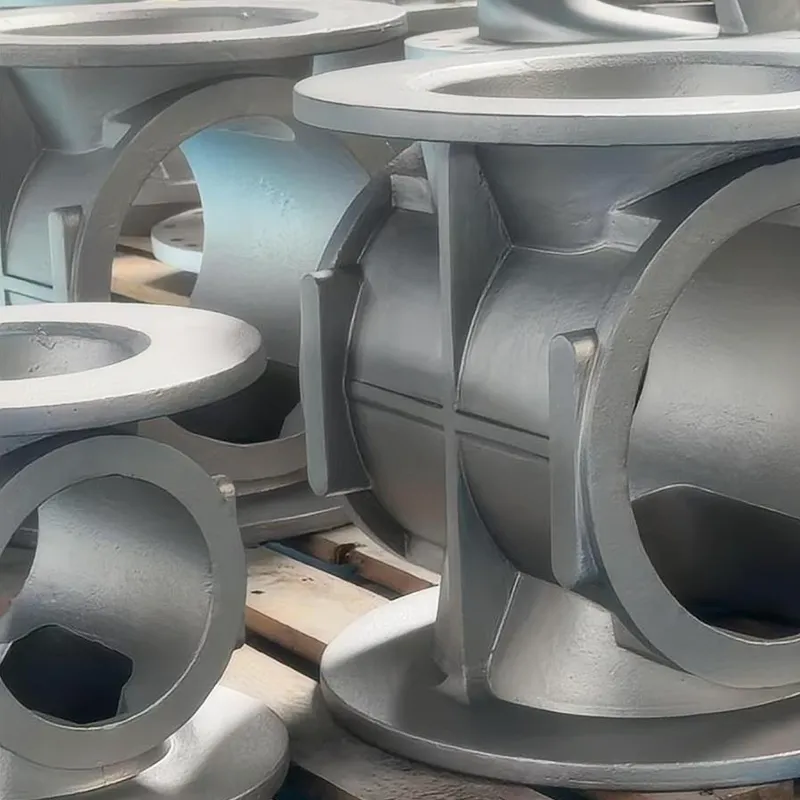

Lost foam casting is an advanced casting technique that uses a foam pattern as the primary mold. Its core principle is to replace traditional molds with foam patterns; during pouring, the high-temperature molten metal vaporizes the foam and fills the cavity. This process, combined with no-binder dry sand molding technology, eliminates the traditional mold parting, core removal, and assembly steps.

This process can efficiently produce complex hollow structures (such as automotive engine blocks and hydraulic valve bodies) and ultra-thin-walled components (wall thickness as low as 1 mm). Its dimensional tolerance is ±0.5 mm, surface roughness is Ra 12.5-25 μm, material utilization rate exceeds 95%, and machining allowance is reduced by more than 30%.

The dry sand recovery rate of this method is ≥98%, and there is no chemical binder pollution. Compared with traditional processes, energy consumption is reduced by 20%-30%, and the production cycle is shortened by 40%. It combines high precision, low cost, and environmentally friendly manufacturing, making it particularly suitable for precision parts in the automotive and aerospace industries, as well as art castings.

Lost foam casting is an innovative solution for mass production of complex metal parts, especially suitable for situations requiring complex geometries, lightweight designs, and low costs. It is particularly advantageous in small-batch customization and environmentally demanding applications, making it an ideal choice for the automotive, machinery, art casting, and specialized industrial fields.

■ Applicable Materials

304 Stainless Steel, 316L Stainless Steel

More Products

Casting process products

-

Investment casting

This process involves: fabricating a meltable wax model using a CNC machine or 3D printing → coating the wax model with multiple layers of silicon sol and zircon sand to form a ceramic shell → steam dewaxing to form a cavity → casting molten alloys (such as stainless steel, titanium alloy or superalloys) → breaking the shell to remove the finished part.

-

Lost foam casting

Lost foam casting is an advanced casting technology that uses a foam pattern as the main mold. Its core principle is to replace the traditional mold with a foam pattern; during pouring, the high-temperature molten metal vaporizes the foam and fills the cavity.

-

Sand casting

Sand casting is one of the most traditional metal forming processes, using quartz sand or special sand combined with clay or resin binders to make molds. Metal parts can be produced by gravity or pressure casting.

-

Resin sand casting

Resin sand casting: Uses resin as a binder, mixed with sand to form a mold. Resin sand casting has low mold costs and is suitable for large and complex castings, generally used for machine tools, lathes, large machinery bases, etc.

Filter Pump Body

Multistage Pump Body

-

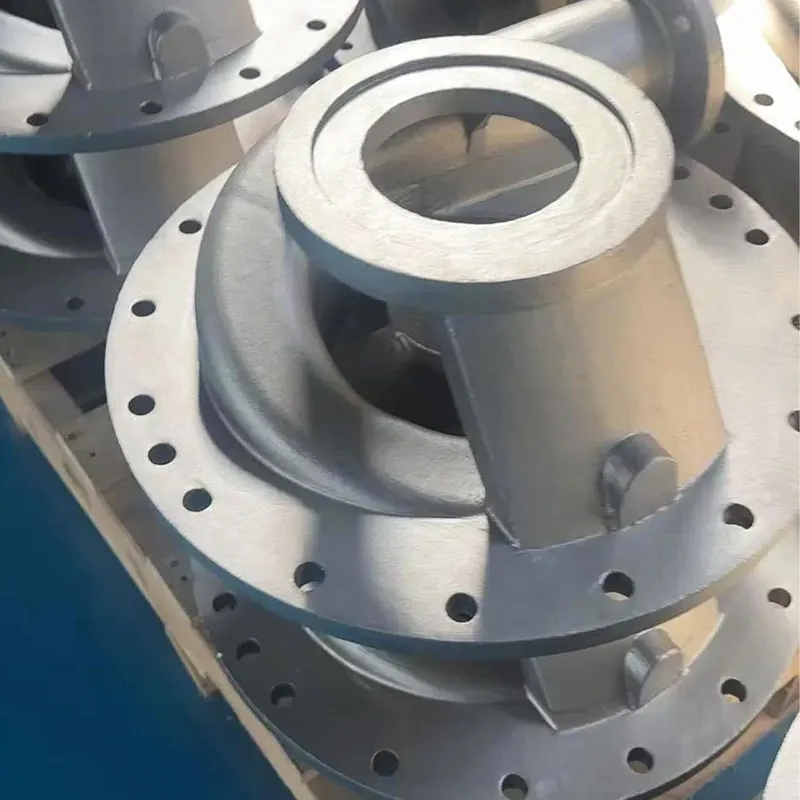

Multistage pump bodies

Expertise in manufacturing products with complex structures: equipped with advanced casting simulation software to assist in process and product design.

-

Roots blower pump body

The company specializes in the research and development, production, and sales of a wide range of high-quality pump bodies and Roots blower components.

Double-Suction Pump Body

-

350S44 Double-suction pump bodies

Linear dimensions: GB/T 1800.1-2009 standard grade 5-7; Geometric dimensions: GB/T 1800.1-2009 standard grade 6-8.

-

Double-suction pump bodies

These products are widely used in industries such as chemical engineering, petroleum, pharmaceuticals, electric power, environmental protection, and metallurgy, providing reliable fluid transfer solutions for numerous enterprises worldwide.

Mixed-Flow Pump Body

Vacuum Pump Body

Chemical Pump Body

Roots Blower Components

-

Roots blower components

Expertise in manufacturing products with complex structures: equipped with advanced casting simulation software to assist in process and product design.

-

Multi-stage pump guide vanes

Its main products include double-suction pump bodies, multistage pump bodies, mixed-flow pump bodies, vacuum pump bodies, Roots blower accessories, chemical pump bodies, as well as impellers.

Impeller

-

Impeller (Paper machinery industry)

Stainless steel, carbon steel, low alloy steel, medium alloy steel, copper alloy, aluminum alloy, nickel-based alloy, cobalt-based alloy, etc.

-

Impeller

Stainless steel, carbon steel, low alloy steel, medium alloy steel, copper alloy, aluminum alloy, nickel-based alloy, cobalt-based alloy, etc.