Products

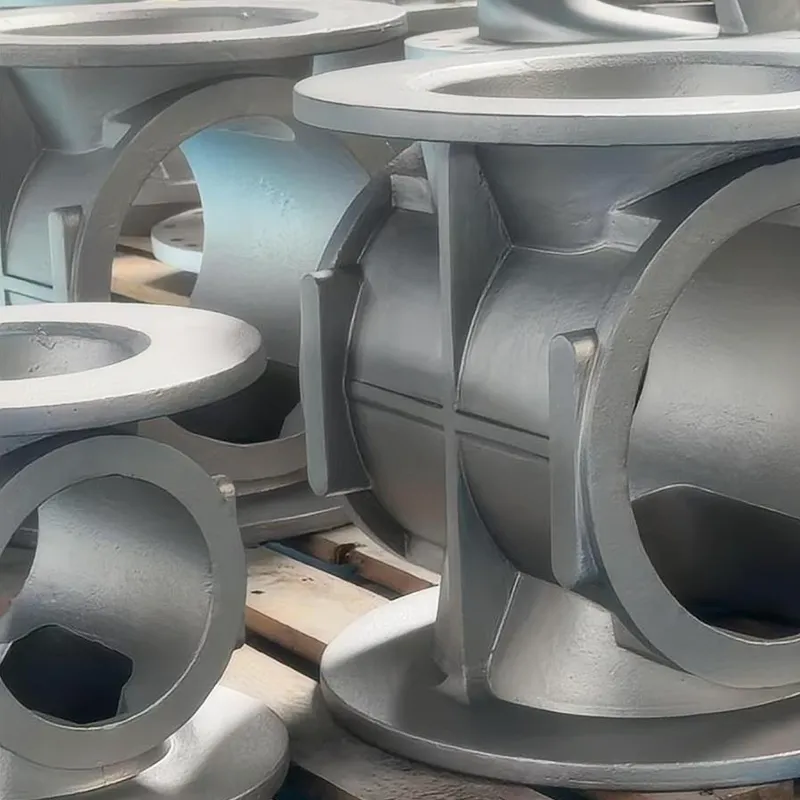

Resin sand casting

Keywords:

Resin sand casting

- Details

-

Resin sand casting: Using resin as a binder, mixed with sand to form a sand mold. Resin sand casting has low mold costs and is suitable for large and complex castings, generally used for machine tools, lathes, large machinery bases, etc.

■ Process Advantages

High flexibility: Suitable for the manufacture of parts with various complex shapes, allowing for flexible adjustment of casting design, easy batch production, and meeting the diverse needs of different customers.

Good surface quality: The surface of the casting is smooth and free of obvious defects, greatly reducing subsequent surface treatment processes, lowering production costs, and improving production efficiency.

High precision: Able to produce castings with high dimensional accuracy, effectively controlling the dimensional deviation of castings and meeting various high-precision engineering requirements.

High production efficiency: Short preparation cycle, the entire process from mold making to casting formation is relatively short, allowing for rapid production, suitable for large-scale and high-efficiency production.

Relatively low cost: Compared to some other casting processes, such as investment casting, resin sand casting has lower equipment investment and production costs, and is more economical.

High sand mold strength: After hardening, resin sand has high strength and rigidity, able to withstand the scouring and pressure of molten metal, not easily deformed or damaged, which helps to ensure the quality of the castings.

■ Application Areas

Automotive manufacturing: Used to produce engine blocks, cylinder heads, transmission housings, brake system parts, etc., precisely controlling the size and shape of castings to ensure the quality and performance of automotive parts.

Aerospace industry: Resin sand casting is often used in the manufacturing of aircraft engine parts and fuselage structural components. By adding alloying elements, the strength and toughness of the castings can be improved to meet the high-performance requirements of the aerospace industry for parts.

Engineering machinery industry: Such as excavator bucket teeth, bulldozer blades, mining equipment parts, etc., resin sand casting can produce high-performance, wear-resistant engineering machinery parts, extending their service life.

Power equipment industry: Can be used to manufacture generator set components, transformer cores, high-voltage switchgear housings, etc., precisely controlling the size and shape of castings to ensure the stable and reliable operation of power equipment.

Shipbuilding industry: Manufacturing of marine diesel engine parts, propellers, hull structural components, etc., resin sand casting can meet the high requirements of ship parts for precision and strength, ensuring the sailing performance and safety of ships.

Rail transit industry: Train wheel hubs, bogie parts, subway car body structural components, etc., resin sand casting can precisely control the size and shape of castings to ensure the smooth and reliable operation of rail transit equipment.

Machine tool manufacturing industry: Castings such as machine tool beds, columns, beams, worktables, and spindle boxes, resin sand casting can achieve high-precision molding, ensuring the precision and stability of machine tools at high speeds.

■ Applicable Materials

304 stainless steel, 316L stainless steel, 2202 stainless steel, 2507 stainless steel, 904L stainless steel, 2205 stainless steel, 1Cr18Ni9Ti, CD4mcu

More Products

Casting process products

-

Investment casting

This process involves: fabricating a meltable wax model using a CNC machine or 3D printing → coating the wax model with multiple layers of silicon sol and zircon sand to form a ceramic shell → steam dewaxing to form a cavity → casting molten alloys (such as stainless steel, titanium alloy or superalloys) → breaking the shell to remove the finished part.

-

Lost foam casting

Lost foam casting is an advanced casting technology that uses a foam pattern as the main mold. Its core principle is to replace the traditional mold with a foam pattern; during pouring, the high-temperature molten metal vaporizes the foam and fills the cavity.

-

Sand casting

Sand casting is one of the most traditional metal forming processes, using quartz sand or special sand combined with clay or resin binders to make molds. Metal parts can be produced by gravity or pressure casting.

-

Resin sand casting

Resin sand casting: Uses resin as a binder, mixed with sand to form a mold. Resin sand casting has low mold costs and is suitable for large and complex castings, generally used for machine tools, lathes, large machinery bases, etc.

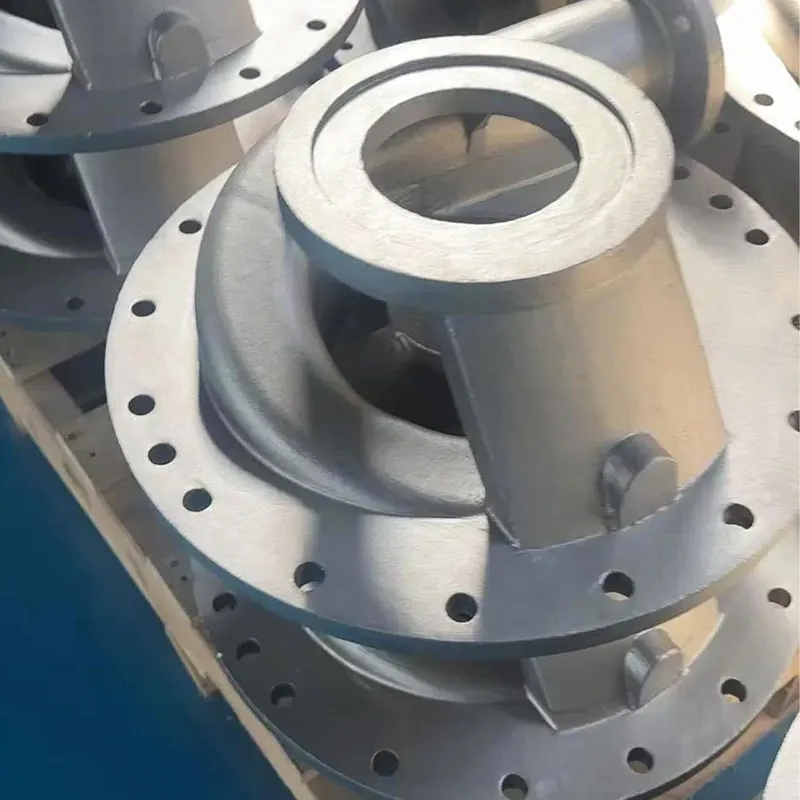

Filter Pump Body

Multistage Pump Body

-

Multistage pump bodies

Expertise in manufacturing products with complex structures: equipped with advanced casting simulation software to assist in process and product design.

-

Roots blower pump body

The company specializes in the research and development, production, and sales of a wide range of high-quality pump bodies and Roots blower components.

Double-Suction Pump Body

-

350S44 Double-suction pump bodies

Linear dimensions: GB/T 1800.1-2009 standard grade 5-7; Geometric dimensions: GB/T 1800.1-2009 standard grade 6-8.

-

Double-suction pump bodies

These products are widely used in industries such as chemical engineering, petroleum, pharmaceuticals, electric power, environmental protection, and metallurgy, providing reliable fluid transfer solutions for numerous enterprises worldwide.

Mixed-Flow Pump Body

Vacuum Pump Body

Chemical Pump Body

Roots Blower Components

-

Roots blower components

Expertise in manufacturing products with complex structures: equipped with advanced casting simulation software to assist in process and product design.

-

Multi-stage pump guide vanes

Its main products include double-suction pump bodies, multistage pump bodies, mixed-flow pump bodies, vacuum pump bodies, Roots blower accessories, chemical pump bodies, as well as impellers.

Impeller

-

Impeller (Paper machinery industry)

Stainless steel, carbon steel, low alloy steel, medium alloy steel, copper alloy, aluminum alloy, nickel-based alloy, cobalt-based alloy, etc.

-

Impeller

Stainless steel, carbon steel, low alloy steel, medium alloy steel, copper alloy, aluminum alloy, nickel-based alloy, cobalt-based alloy, etc.