Products

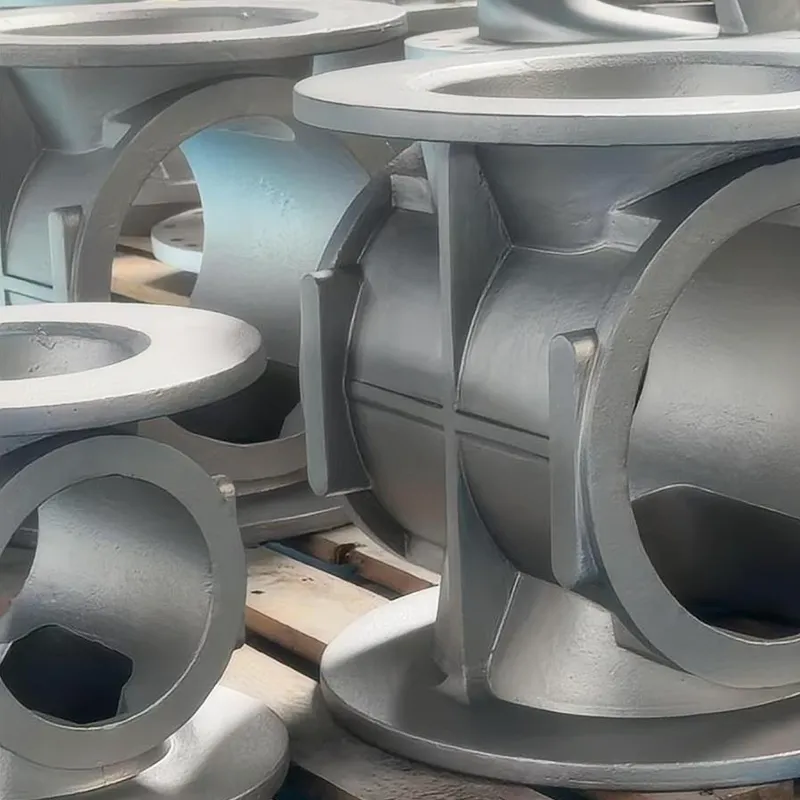

Sand casting

Keywords:

Sand casting

- Details

-

Sand casting is one of the most traditional metal forming processes, using quartz sand or special sand combined with clay or resin binders to create molds. Metal parts can be produced through gravity or pressure casting.

■ Core Functions and AdvantagesHigh Adaptability:

Able to cast various metals, including cast iron, cast steel, and aluminum alloys, with weights ranging from a few kilograms to several hundred tons.

Highly suitable for producing extra-large parts, such as machine tool bases and ship propellers, with unlimited wall thickness (starting from 3 mm).

High Cost-Effectiveness:Raw material (sand and binder) costs are only 10%-20% of investment casting.

Low mold cost (wooden mold or 3D printed sand mold).

Suitable for mass production (up to tens of thousands of pieces).

Flexible Process Options:Manual molding: Suitable for customized single-piece production.

Machine injection molding: Using isostatic pressing lines for efficient production.

Supports integration of cold/hot core box technology to create complex internal cavities.

Environmentally Friendly and Controllable:Sand recycling rate reaches 90%-95% (through crushing, screening, and dust removal).

New inorganic binders can reduce volatile organic compound emissions by more than 50%.

Stable Quality:Optimized gating and riser systems combined with permeable sand molds (permeability >100) effectively control shrinkage and inclusion defects.

Casting yield exceeds 95%.■ Applicable Materials

304 stainless steel, 316L stainless steel, 2202 stainless steel, 2507 stainless steel, 904L stainless steel, 2205 stainless steel, 1Cr18Ni9Ti, CD4mcu

■ Typical Applications

● Heavy Machinery: Rolling mill housings and large machine tool bases

● Energy Equipment: Wind turbine hubs and large engine components.

● Architectural Hardware: Manhole covers, pipes, and municipal infrastructure components.

● Art Castings: Large sculptures and monuments.

■ Performance ConsiderationsPrecision and Surface Finish:

Dimensional tolerance: ±1.5mm (lower than investment casting).

Surface roughness: Ra 25-50μm (not as smooth as investment casting).

■ Core Advantages"Low cost, large size, high compatibility" capabilities.

Best suited for applications requiring cost sensitivity, high volume, or extra-large/heavy components.■ Industry Positioning

Sand casting remains indispensable in heavy machinery, energy infrastructure, shipbuilding, and traditional industries. It is the preferred process for large cast iron and cast steel components, especially suitable for cost-sensitive, high-volume, or extra-large/heavy metal products. Despite limitations in precision and surface quality, its unparalleled scalability underpins global industrial systems.

More Products

Casting process products

-

Investment casting

This process involves: fabricating a meltable wax model using a CNC machine or 3D printing → coating the wax model with multiple layers of silicon sol and zircon sand to form a ceramic shell → steam dewaxing to form a cavity → casting molten alloys (such as stainless steel, titanium alloy or superalloys) → breaking the shell to remove the finished part.

-

Lost foam casting

Lost foam casting is an advanced casting technology that uses a foam pattern as the main mold. Its core principle is to replace the traditional mold with a foam pattern; during pouring, the high-temperature molten metal vaporizes the foam and fills the cavity.

-

Sand casting

Sand casting is one of the most traditional metal forming processes, using quartz sand or special sand combined with clay or resin binders to make molds. Metal parts can be produced by gravity or pressure casting.

-

Resin sand casting

Resin sand casting: Uses resin as a binder, mixed with sand to form a mold. Resin sand casting has low mold costs and is suitable for large and complex castings, generally used for machine tools, lathes, large machinery bases, etc.

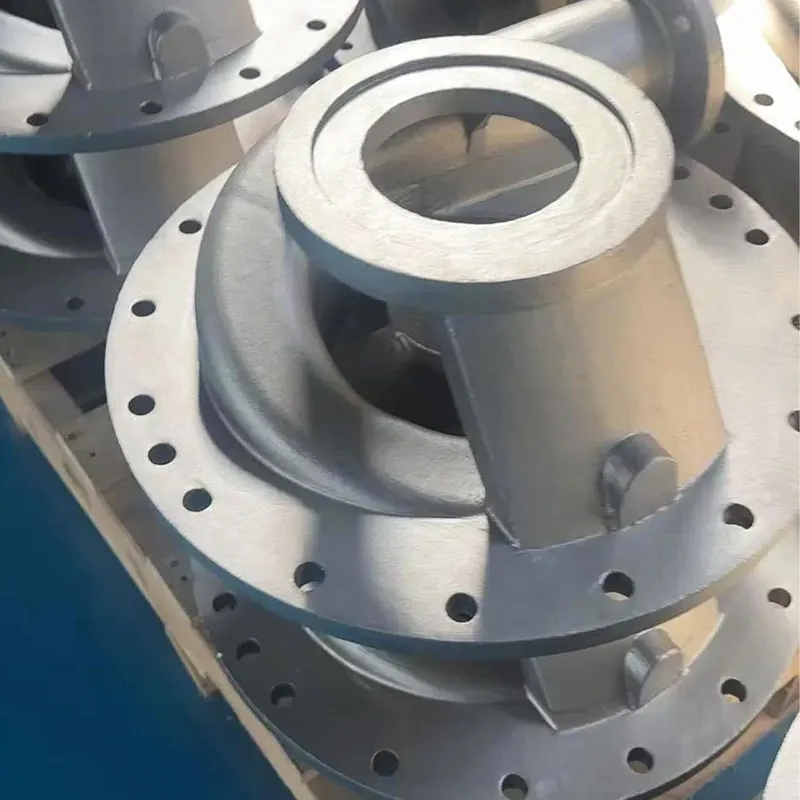

Filter Pump Body

Multistage Pump Body

-

Multistage pump bodies

Expertise in manufacturing products with complex structures: equipped with advanced casting simulation software to assist in process and product design.

-

Roots blower pump body

The company specializes in the research and development, production, and sales of a wide range of high-quality pump bodies and Roots blower components.

Double-Suction Pump Body

-

350S44 Double-suction pump bodies

Linear dimensions: GB/T 1800.1-2009 standard grade 5-7; Geometric dimensions: GB/T 1800.1-2009 standard grade 6-8.

-

Double-suction pump bodies

These products are widely used in industries such as chemical engineering, petroleum, pharmaceuticals, electric power, environmental protection, and metallurgy, providing reliable fluid transfer solutions for numerous enterprises worldwide.

Mixed-Flow Pump Body

Vacuum Pump Body

Chemical Pump Body

Roots Blower Components

-

Roots blower components

Expertise in manufacturing products with complex structures: equipped with advanced casting simulation software to assist in process and product design.

-

Multi-stage pump guide vanes

Its main products include double-suction pump bodies, multistage pump bodies, mixed-flow pump bodies, vacuum pump bodies, Roots blower accessories, chemical pump bodies, as well as impellers.

Impeller

-

Impeller (Paper machinery industry)

Stainless steel, carbon steel, low alloy steel, medium alloy steel, copper alloy, aluminum alloy, nickel-based alloy, cobalt-based alloy, etc.

-

Impeller

Stainless steel, carbon steel, low alloy steel, medium alloy steel, copper alloy, aluminum alloy, nickel-based alloy, cobalt-based alloy, etc.